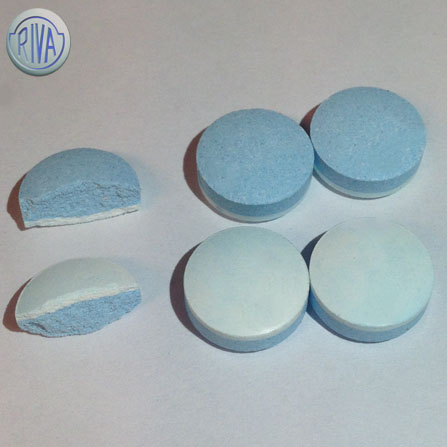

Piccola Bilayer

DESIGNED FOR RESEARCH & DEVELOPMENT FOR DOUBLE LAYER TABLETS

This rotary tablet press was designed to represent the production conditions of a production bi-layer tablet press.

The equipment is controlled from an Industrial PC with a touch screen panel, which is provided with software that allows obtaining all the parameters settings, including the production speed and the individual speed of the paddle feeders, weight adjustment, thickness and hardness (both for the first and second layer), and the use of data obtained to perform the calculations and statistics.

Easy cleaning and sterilization is to be highlighted, as well as the quick disassembly of hoppers, feeders and tooling change over. It also features two product hoppers with rotary paddle feeders, a pre-compression system, independent vacuum intakes to recover the product separately, speed variation, and a hydropneumatic pressure compensation system.

The Piccola Bi-Layer is available to run with standard EU/TSM tooling according to the customer requirements.